Ensuring color uniformity throughout the supply chain requires robust safeguards and an insightful grasp of how to manage color. One aspect that needs to be considered? Light sources and the way they affect our color perception.

Given the subjective nature of color evaluation, it’s understandable that lighting sources pose a significant challenge towards achieving color consistency. The hue of light used for visual color evaluation is typically established at the beginning of the production process. Nonetheless, any lack of color uniformity across the supply chain can result in a vastly different or even inconsistent end product.

The impact of color temperature on lighting

While lighting choices span myriad brands and models, one common thread ties them together: color temperature. Expressed in degrees Kelvin , color temperature scale (e.g. 6,500 K) is a universal measurement that groups lighting into similar color families. The lower the color temperature of the light source, the warmer or redder the source will be. The higher the color temperature, the cooler or bluer it will be.

Note that fluorescent lights were historically assigned generic names instead of color temperatures. Today, fluorescent lights also have a corresponding color temperature. The chart below indicates the color temperature associated with each type of fluorescent light.

| Name |

Color Temperature |

| CWF (CIE F02) |

4,150K |

| WWF, TL83, U30 |

3,000K |

| TL84 (CIE F11) |

4,100 |

| TL835, SPX, U35 |

3,500K |

What you need to know about types of light sources

A vast array of lighting products exists to support color evaluation. Most produce light energy via one of the following methods:

Incandescent and Tungsten Filament

A tungsten filament glows when electricity is passed through it. The downside? It generates a lot of wasted energy, so tungsten filament is less common in today’s market. Also in the incandescent category are quartz halogen lamps. Specially formulated to give a more uniform output over time, quartz halogen lamps are used when a yellowish to red source is required.

Fluorescent

Fluorescent light sources produce light when electrical energy is applied to a glass tube containing mercury together with fluorescent compounds called phosphors. By adjusting the types of phosphors in the lamp, lighting manufacturers can produce fluorescent tubes in a variety of styles and color temperatures.

LED

While light-emitting diodes (LEDs) have been used in electronics for more than 50 years, the now-ubiquitous light source owes its prevalence in retail and consumer environments to the relatively recent advent of white LEDs. Offering significantly improved energy efficiency compared to other types of lighting, LEDs are quickly becoming the light source of choice for retail, office and home environments. To ensure consistency at retail, color must be developed and evaluated under comparable LED lighting conditions during production.

Ultra-Violet

Although not visible to the human eye, ultra-violet (UV) light energy is present in natural daylight. UV energy is used to catalyze optical brightening agents (OBAs) and fluorescent dyes and pigments within a sample, causing them to emit visible light. This phenomenon makes white materials appear whiter and brighter than they would without the OBAs, while fluorescent colors exhibit the classic neon effect.

Things to consider when working with a new light source

Lighting choices can have a significant impact on color consistency, product quality and brand perception. Understanding the impact of a new light source is key to choosing a solution that will maintain color uniformity across the supply chain and result in an accurate finished product.

It is vital to consider the impact any change in light source will have on the perceived color of your company’s standards and existing products. Color fluctuations fall into two categories:

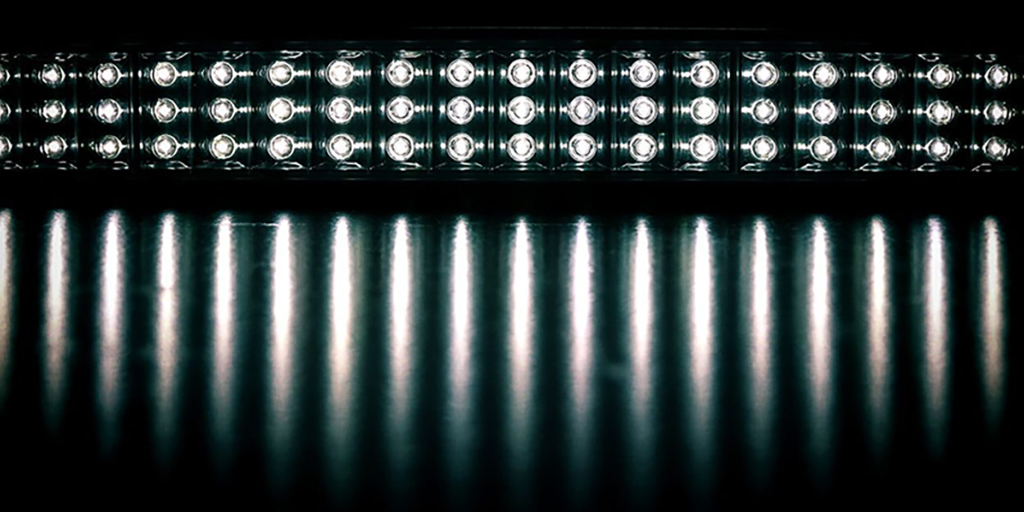

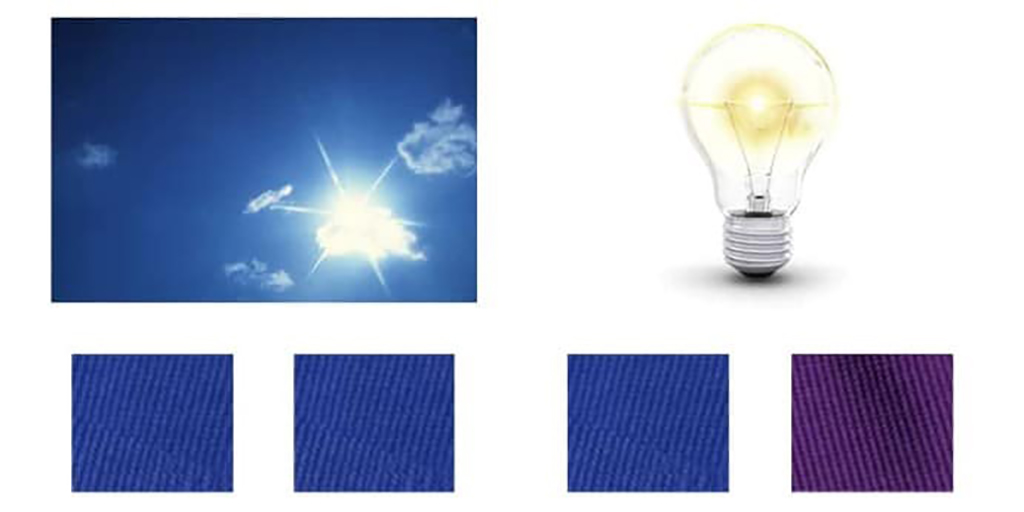

Flare – A change in the color of a material when it is viewed under different light sources.

Metamerism – Occurs when two samples match under one lighting condition, but no longer match under another lighting condition.

Noticeable variations in flare or metamerism may be perceived differently, depending on who is conducting the color evaluation. That’s why it’s crucial to engage key stakeholders in the lighting selection process. While these people will vary depending on your industry and company, here are some potential stakeholders for a textile brand:

Designers

A new light source can alter the designer’s color selection and impact the overall aesthetic of the final product. Input from the design team is essential to preserving the integrity of the original vision.

Merchandisers

The seasonal color palette must be evaluated in the new light source to ensure that individual colors do not flare in an unacceptable direction.

Color Team

The retail/apparel color team typically is responsible for implementing the global color management workflow, so open communication with color professionals is a prerequisite for success across the supply chain.

Suppliers

A critical factor in color uniformity is streamlined standards. It’s critical to ensure that suppliers can match existing and new colors to your company’s standards under the new light source.

Color Evaluators

Anyone who evaluates color will need a light booth equipped with the proper light source, and color management software must be updated to calculate color differences caused by lighting changes.

Customers

Keep the end user in mind. Your light source selection should support a positive customer experience in the retail environment to boost brand perception and sales.

Building a Plan: How to implement a new light source

To avoid surprises when implementing a new light source into the color development process, begin with a well-defined plan rooted in a proactive approach. A coordinated plan, thoughtfully executed, ensures specific challenges can be addressed by key stakeholders before any issues reach the retail shelf.

Follow these tips to successfully implement a new light source:

- Timing determines the urgency of each step, so consider when the transition to a new light source must be completed and build your project timeline accordingly.

- Consider who will be impacted by the transition to a new light source, and identify how their specific concerns will be incorporated into the color evaluation and transition process.

- Equip light booths within the company and across the supply chain with matching light sources.

- Ensure that matching light source data is available in color management software within the company and across the supply chain.

- Engage key stakeholders to determine the impact on flare and metamerism before implementing a new light source.

The Road to Implementation: Choosing an approach that works for your business

Your key stakeholders are aligned; now it’s time to implement one of the following approaches:

- If your products will be sold in-store, pick a light source for color development that is identical to the in-store light source and require its use by vendors and suppliers. This may precipitate a more complex color development process and the use of additional equipment.

- Pick a light source that is as close as possible to the one being replaced, then continue using the original light source for color development. No additional color development work is required, but it may be difficult to find a new light source that matches the original.

- Adjust color standards to minimize flare. Changing dyes can produce color constant standards that will look the same regardless of light source, but a significant amount of color development re-work may be needed.

The Final Stop: Following industry standards to ensure accuracy

Even the most well-defined plan requires a commitment to accuracy and repeatability. Industry standards for color viewing booths have been established for color quality, light intensity, evenness of illumination, viewing/illumination geometry, and surrounding conditions. Differences in any of these conditions may affect color appearance and result in inaccurate color quality decisions. The best way to ensure accuracy and repeatability when evaluating color samples is to use a color viewing booth that meets industry specifications.

For more ideas on implementing the right lighting source and to explore our comprehensive suite of color management software, instruments and services, connect with a Datacolor specialist today.