- Color Management Solutions

- Benchtop Spectrophotometers

- Portable Spectrophotometers

- Color Management Software

- Color Quality Control Software: Datacolor Tools

- Cloud Color Quality Control Software: CloudQC

- Pigment Formulation Software: Match Pigment

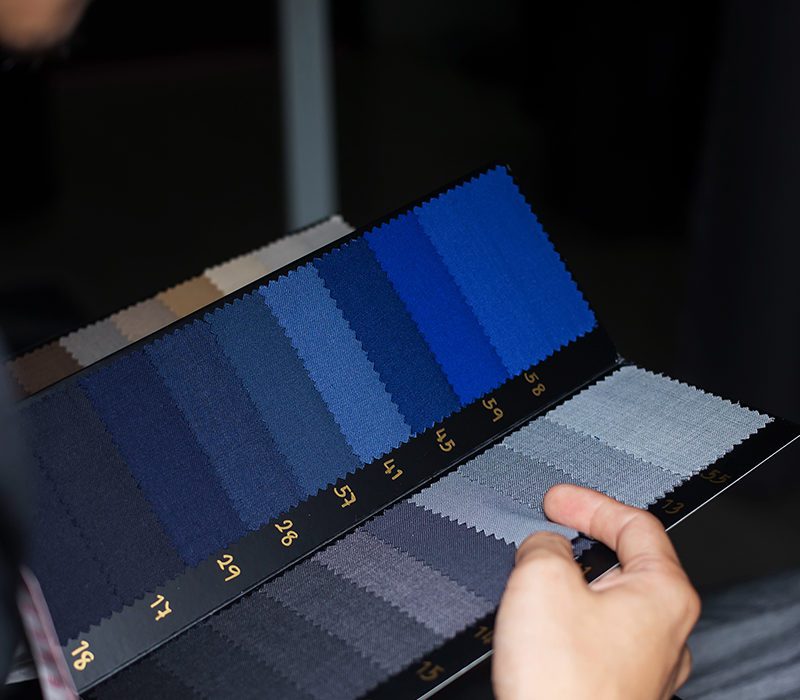

- Dyer Color Formulation Software: Match Textile

- Dye Production Optimization Software: Process, Ticket and Weigh

- Dye Production Optimization Software: Weigh

- Retail Paint Software: Paint

- Visual Evaluation & Lab Tools

- Color Audit Services: Assessment Services

- Colibri Platform

- Benchtop Spectrophotometers

- Learning Center

- Customer Support

MENUMENU

- Color Management Solutions

-

-

- Color Management Software

- Color Quality Control Software: Datacolor Tools

- Cloud Color Quality Control Software: CloudQC

- Pigment Formulation Software: Match Pigment

- Dyer Color Formulation Software: Match Textile

- Dye Production Optimization Software: Process, Ticket and Weigh

- Dye Production Optimization Software: Weigh

- Retail Paint Software: Paint

-

- Learning Center

-

-

- Hands On Courses, Color Training + Learning Seminars

- Options include classroom style seminars, bring a trainer on-site to your organization, or attend a virtual learning session.

-

- Upcoming Events

-

Find Datacolor on the move at industry trade shows or join us for an upcoming virtual or in-person event.

-

- Customer Stories

- Discover how Datacolor has transformed processes and outcomes for businesses across the globe.

-

- Color Science Essentials

-

Learn the fundamentals of color science and stay up-to-date with how-to articles, webinars, and more.

-

-

- Customer Support

-

-

- FAQ

- Explore the most frequently asked questions about your color devices, software, and services.

-

- Informative User, Quick Start and Installation Guides

- View and download documentation for your Datacolor hardware and software.

-

- Support Services

- Obtain access to a dedicated support team by signing up for a support plan.

-

- Colibri Software

- Supported versions and downloads

-

-