Automation

Automating the paint formulation and analysis process

Lab automation is the process in which tools and equipment can be controlled with minimal interaction. Laboratory automation is the integration of automated technologies into the laboratory to enable new and improved processes.

Today’s busy laboratories face increasing pressures to simultaneously improve throughput, efficiency, and quality – stretching their resources and manpower to the absolute limit. As a result, many labs utilize laboratory automation to replace manual, repetitive tasks, increase throughput and improve quality.

The main lab automation benefits are reproducibility (quality), data accuracy, traceability, efficiency, and safety.

With hundreds of thousands of unique colors in their repertoire, PPG is one of the largest paint manufacturers in the world.

Because PPG has so many colors with different gloss levels and indoor/outdoor variations, making a change to one of the colorants in their paint results in an incredibly time-consuming process.

When a change is made, PPG’s manufacturing plants must create new formulas, produce test batches, correct mis-tints and then distribute the final product to stores while also updating the database at each individual location.

This already arduous process can easily be disrupted by unforeseen circumstances. Raw materials shortages and supply chain issues, among other obstacles, can snarl speed-to-market and increase costs the often get passed down to consumers.

To reduce risk and provide the best possible product at the best possible price without sacrificing variety, PPG partnered with a leading robotics company and Datacolor to streamline their color formulation process.

Together, PPG, Datacolor and the robotics company set their sights on achieving four main objectives:

Automating the paint formulation and analysis process

Seamlessly integrating Datacolor color management hardware and software with the new robotic systems

Reducing variations and errors that occur in volumetric dispensing systems

Centralizing the color database to make communication easier between regions

PPG and the robotics company worked together to develop a mechanized system for the color lab that would automatically dispense, mix, and apply paint, print a barcode then dry and measure paint samples and sort results based on pass/fail criteria.

The system had to meet the following standards:

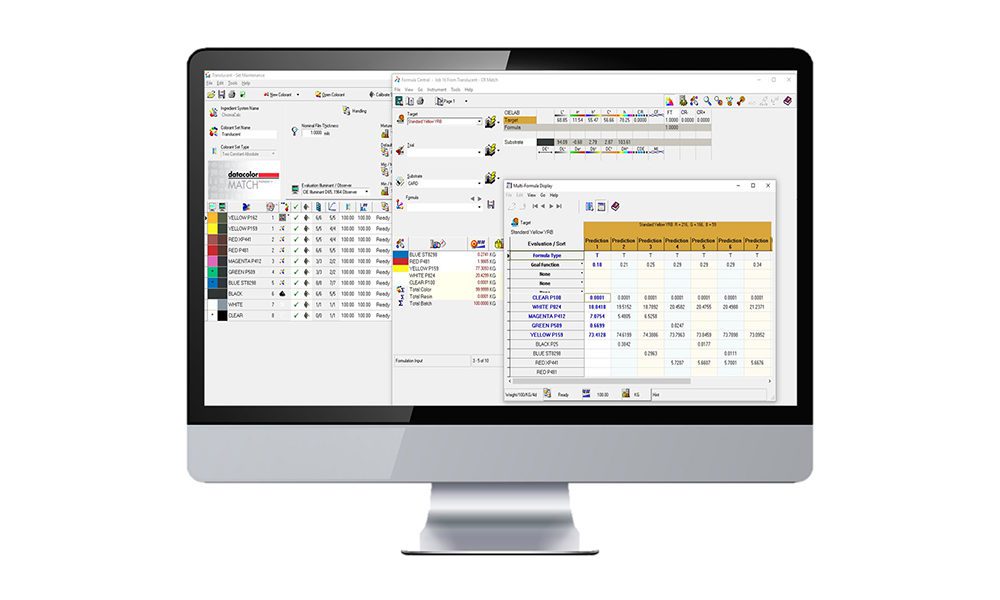

When it came to integrating software and quality control equipment, Datacolor was an easy choice for PPG because of a 20+ year history working together.

The Datacolor applications team worked closely with the robotics developer to integrate a Match Pigment database and Datacolor 800 spectrophotometer to ensure accurate color formulations.

Through our collaborative efforts, the HITMAN – High Throughput Color Matching Automation – robotic system was born.

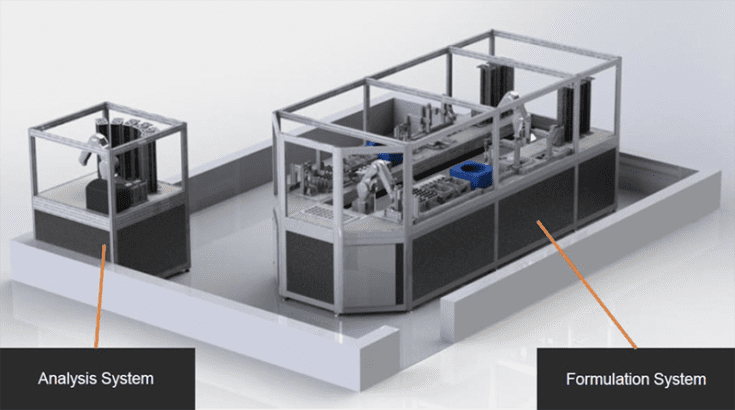

To meet PPG’s standards and goals, two separate systems were created within HITMAN.

Formulation System | The formulation system dispenses base paints and colourants in the pot as per the sample recipes. Pots are them mixed to create the sample, which are then applied on cards and dried in carousel racks.

Analysis System | The analysis system is loaded with cards from the formulation system. These are presented to a Datacolor Spectro 800 spectrophotometer for analysis and the measurements are stored in a database. An interface with the Datacolor database is used to create new recipe for color adjustment if required.

This process is the same as traditional processes but what makes it unique is its accuracy, speed, and miniaturization of samples.

“There was very good cooperation between Datacolor and the robotics company that built the HITMAN system and wrote the programs for integration with Datacolor software. There were hiccups but we are happy with the output. We are starting a new project soon with an even higher target.”

In the months since PPG began using their new HITMAN system coupled with Datacolor hardware and software, the company has been able to achieve an unprecedented increase in production speed, formula accuracy, cost savings, and more. What used to be a long process is now streamlined enough that PPG can formulate new fan decks and create new products with lightning speed.

After implementing this system, PPG was able to improve their production speed. Because PPG can now create colors more efficiently, the time it takes to reach the final consumer is significantly reduced. Not only does this help keep store shelves stocked, but it also helps PPG keep up with ever evolving trends and tastes.

With the new automated dispensers, formulas now come from Datacolor’s MatchPigment software. This system has far better accuracy than traditional dispensers in the market today.

The new dispensing system also allowed PPG to reduce sample sizes from 500ml to 75ml. Previously this kind of accuracy was not possible, and a lot of waste was created if a customer ended up going in a different direction with their color choices. The new dispensers save materials and reduce the amount of paint being disposed of, thereby limiting environmental impacts and the cost of recycling.

“The actual power of the system is that it’s much more accurate and precise. A traditional dispenser that dispenses volumetrically isn’t very accurate below 500ml but with the new system we have a lot more control,” Parag explains.

In order to keep costs down, PPG has moved their database of colors and formulas to a centrally hosted location rather than individually across the marketplace. As a result, PPG can offer their customers wide-ranging, accurate colors in a short timeframe.

“There is cost involved to match one color recipe – we calculate all the costs – materials, overhead, packaging, etc. – and depending on the location, the cost can be quite substantial,” says Parag. “If we need to match the same color different times at different stores around the world, the cost can be up 100 times that – and it would stay outside of the central database. Now (with Datacolor Match Pigment) we can generate and handle all the data centrally in a higher quality-controlled environment. Then it is suitable to use Datacolor ColorReader for the final consumer to search for their closest color.”

The Datacolor ColorReader is a handheld, portable and affordable spectrophotometer that measures colors and recommends the best match across all PPG paints.

This easy-to-use tool adds great value for designers and paint professionals who are on a tight schedule. With the ColorReader, they can quickly measure a color in stores with the click of a button and be paired with PPG’s closest match, which eliminates time spent sifting through paint chip samples looking for the right color.

• Customer Stories •

Success comes in different forms for different clients. Discover more ways Datacolor delivers. See More Stories ›

When data meets color, inspiration meets results.