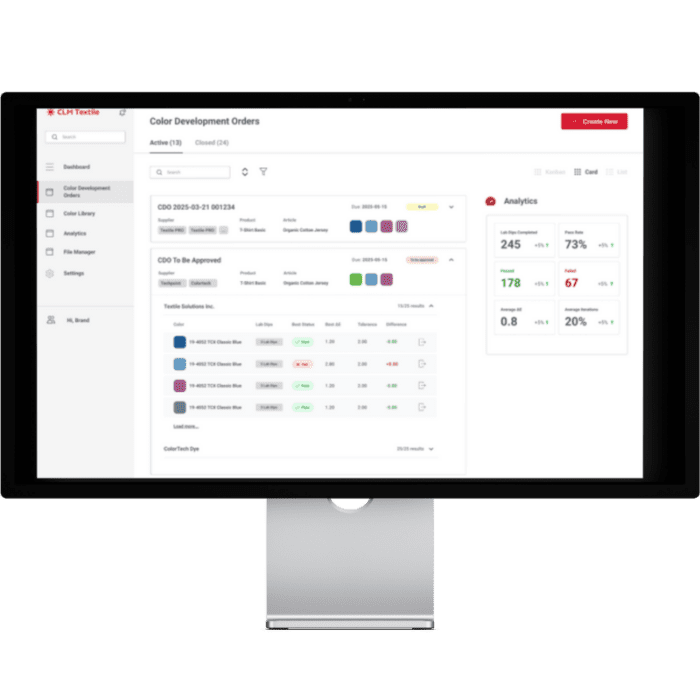

Designed for brands, suppliers, and manufacturing partners who need fast, reliable, and consistent color alignment, Datacolor Color Lifecycle Management centralizes every color request, standard, and evaluation into one platform. All information arrives with complete context including tolerances, instrument conditions, illuminants, and supporting documents, removing uncertainty and reducing rework.

By replacing manual communication with structured digital workflows, Color Lifecycle Management shortens development cycles, improves color accuracy, and eliminates the confusion caused by fragmented email chains and outdated files. Real time visibility allows all partners to collaborate more effectively, reduce physical samples, and make informed decisions backed by performance data.

Benefits of Datacolor CLM

Centralized digital collaboration

- Manage every color request in one place with a complete audit trail

- Ensure all partners work from the correct standard, tolerances, and conditions

- Remove communication gaps, outdated files, and version inconsistencies

Faster approvals and reduced sampling

- Clear digital workflows reduce the number of iterations required

- Approve colors in days instead of weeks with immediate status visibility

- Reduce shipping and lab dip costs by minimizing physical samples

Improved color consistency across the supply chain

- Align color from Lab Dip to SMS to Bulk regardless of supplier or region

- Prevent shade variation with structured pass or fail rules and cross material checks

- Increase right-first-time performance with accurate digital guidance

Stronger brand–supplier collaboration

- Shared platform eliminates confusion about instructions, settings, or expectations

- Suppliers receive complete context for each request, improving turnaround and reliability

- Better transparency strengthens trust and supports long term partnerships

Actionable analytics for operational improvement

- Track performance metrics such as right-first-time rates, lead times, and workload

- Evaluate supplier capabilities and benchmark production outcomes

- Use data to improve planning, quality, and strategic sourcing decisions

Support for sustainable workflows

- Fewer sampling rounds reduce waste and CO2 emissions

- More accurate communication reduces material and time losses

- Digital processes support responsible development practices