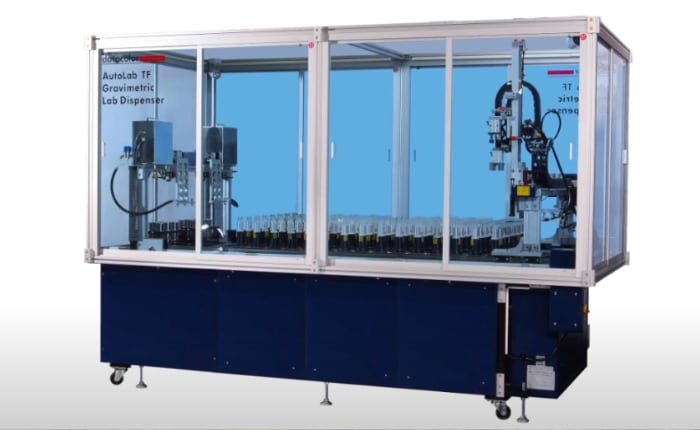

Autolab TF Lab Series Includes

Dispenser system complete, solution bottles, dispense Injectors, dispense scale, dyepot trays, Autolab dispense software, installation and user manuals, installation hardware kit, and ready spare parts kit.

| Autolab TFD Hardware |

Autolab TF Hardware |

Autolab TF Software |

- Dual arm controlled by robotic X-Y-Z axis mechanism

- A tray-feeding conveyor system for continuous dispensing.

- Available in 120 or 160 solution bottles

- 8 self-refilling chemical auxiliary bottles.

- Individual Dispense Injectors for each solution

- The recipe dispensing speed has increased by a factor of 1.3 to over 2.

- Full Gravimetric Dispensing System

- Two scales with a range of 0-4.0 kg

- Precise electronic scales with 0.01 gr readability

- Accuracy of dispense (gravimetric) ± 0.02 gr

- Dyepot quantity per tray is 4(max. 500mL) or 2(max. 1L) or 1

- Dispenses recipes/dyepots quantity at a time: 28 recipes (7 trays)

- Auto-Dilution Feature to make lower concentration of same dyestuffs

- Automatic solution bottle agitation, with speed, interval and direction control

- PC/PLC controlled

|

- Full Gravimetric Dispensing System

- Models available in 40, 80, 120, or 160 Solution bottles.

- Models 88, 128, and 168 offer a tray feeding conveyor system for continuous dispensing and 7 self-refilling chemical auxiliary bottles

- Individual Dispense Injectors for each solution

- Average dispense time for (6 recipes : 3 dyes, 180 cc total volume) is 6 minutes.

- Accuracy of dispense (gravimetric) ± +/- 0.02 gr.

- Dispense range (kg) 0-4.0Kg

- Higher dispense weights available with specialized scale.

- Dispense controlled by robotic X-Y-Z axis mechanism

- Precise electronic scales with 0.01 gr. readability

- Dyepots trays for dispensing recipes (holding up to 6 dyepots)

- Auto-Dilution Feature to make lower concentration of same dyestuffs

- Dispense accuracy of 0.02 grams

- Automatic solution bottle agitation, with speed, interval and direction control

- PC/PLC controlled

- Complete suite of Windows based Dispenser Manager software

|

- User friendly Windows based software

- Graphical data information display, easy to read and understand

- User-definable fields

- Stock solution management (including life time and stock levels)

- Full Recipe Management (including multiple recipe dispense trials, blend recipe handling, master recipe storage and completion function)

- Job queuing, including emergency recipe priority dispense function

- Capability of automatic pre-programmed advanced start dispense function

- Full batch tracking, providing total traceability of results

- Full function hardware diagnostics – easy to diagnose and locate any potential problems

- Real-time status display – the current status and operating conditions of the system is displayed on screen at all times

- Integration with DCIMatch™, Datamatch™, and ITMProcess™ for automatic transfer of recipes to lab dispenser

- Multi-format data import/export capabilities

- Software available in different languages

|

Autolab SPS Includes

Solution Maker System Complete, solution bottles, dispense bottles, dispense scale, 6 position mixing station, autolab SPS software, installation and user manuals, installation hardware kit, and ready spare parts kit.

| Autolab SPS Hardware |

Autolab SPS Software |

- Hot water tank, 15L capacity with automatic refill

- Automatic water heater with programmable temperature controller

- Cold water tank, 5L capacity with automatic refill

- Additional manual controls for all dispense valves

- Precise electronic balance with 0.01g or 0.001gr. readability (SPS-X Model)

- Separate 6-position mixer station for mixing of solutions during preparation

|

- User friendly Windows based software

- True Multi-Tasking Capabilities

- Dyestuff and Auxiliary Data Management

- User Configurable Solution Making Parameters

- Management of Stored Multi-Step Processes

- Dye Solution Management and Stock Control Reporting

- Semi-Automatic and Interactive Solution Making

- Direct Water Dispensing, Accurately Controlled

- Solution Maker Hardware Diagnostic Programs

|

Feature Comparison

|

Autolab

TF-40 |

Autolab

TF-80 |

Autolab

TF-88 |

Autolab

TF-120 |

Autolab

TF-128 |

Autolab

TFD-130 |

Autolab

TF-160 |

Autolab

TF-168 |

Autolab

TFD-170 |

Solution

bottles Qty |

40 |

80 |

80 |

120 |

120 |

60(A area)

60(B area) |

160 |

160 |

80(A area)

80(B area) |

| Measuring method |

Gravimetric |

Gravimetric |

Gravimetric |

Gravimetric |

Gravimetric |

Gravimetric |

Gravimetric |

Gravimetric |

Gravimetric |

Scales

Brands |

Mettler Toledo |

Mettler Toledo |

Mettler Toledo |

Mettler Toledo |

Mettler Toledo |

Mettler Toledo |

Mettler Toledo |

Mettler Toledo |

Mettler Toledo |

Robots

Qty |

Single-Arm |

Single-Arm |

Single-Arm |

Single-Arm |

Single-Arm |

Duo-Arm |

Single-Arm |

Single-Arm |

Duo-Arm |

Scales

Qty |

1 |

2 |

1 |

2 |

1 |

2 |

2 |

1 |

2 |

Scales

Capacity |

6kg |

6kg |

6kg |

6kg |

6kg |

4kg |

6kg |

6kg |

4kg |

Syringe

Capacity |

60ml |

60ml |

60ml |

60ml |

60ml |

60ml |

60ml |

60ml |

60ml |

| Independent Chemicals area |

|

|

|

|

|

|

|

|

|

| Auto-Refill Chemical Qty |

NA |

NA |

7 |

NA |

7 |

4(A area)

4(B area) |

NA |

7 |

4(A area)

4(B area) |

Water lines

Qty |

3 |

3(A area)

3(B area) |

2 |

3(A area)

3(B area) |

2 |

2(A area)

2(B area) |

3(A area)

3(B area) |

2 |

2(A area)

2(B area) |

Auto Tray

Conveyor |

|

|

|

|

|

|

|

|

|

| Glass Safety Shield |

|

|

|

|

|

|

|

|

|

| Dimensions L*W*H (mm) |

1824* 1423* 2007mm |

2350* 1423* 2007mm |

2397* 1725* 2007mm |

2867* 1423* 2007mm |

2923* 1725* 2007mm |

3402* 1423* 2007mm |

2920* 1905* 1825mm |

3449* 1725* 2007mm |

3446* 1905* 1825mm |

| Weight (kg) |

600 |

800 |

900 |

1000 |

1100 |

1200 |

|

1300 |

|

General Environment

- Room temperature should be stable within the limits of 18 to 26 °C

- Humidity should be within the range 40% to 80% RH

- The unit should be installed in a relatively dust-free area, out of direct line of any air-conditioning airflow

- System should be installed in a vibration free environment

Power: 220 V, +/- 10 %, 50/60 Hz. Single phase, 3 wire (live, earth and neutral)

Water Supply

- Mains Water – 1 to 2 kg/cm² (13-26 psi)

- Gravity Drain

Air Supply: A clean and dry air supply is required, no lubrication, 4.5-6.0 kg/ cm² (60-80 psi). (TF ONLY)

PC Requirements for AutoLab TF & SPS systems

- 2.0 (GHz) or faster x86- or x64-bit processor

- 2GB RAM

- High Resolution Color Monitor

- Network Card

- DVD drive

- Windows Operating System (Min. WIN XP/SP3)

- (1) RS232 Com ports required for PC for TF dispenser.

If fabric weigh scale is required to connect to TF dispenser PC, then the TF PC requires (2) RS232 COM ports.

PCs should also include network card/connectors and necessary cabling etc., to allow PCs to be networked together.