Digital solutions: precise color control and process optimization

To cope with these challenges, Xinliang Plastics introduced Datacolor’s DC750 colorimeter and Colibri color matching software to achieve a systematic upgrade of color management.

- Dramatic improvement in color consistency: Colibri software accurately handles the “same color, different spectrum” problem, providing reasonable formulation recommendations in different light source environments.

- Standardization of R&D process: The system reduces human intervention and solves the problem of color difference caused by the difference in personnel operation.

- Improvement of R&D efficiency: Through intelligent matching of the system, the R&D cycle of new product colors is significantly shortened.

The Colibri Software Advantage: Excellence in Complex Scenarios

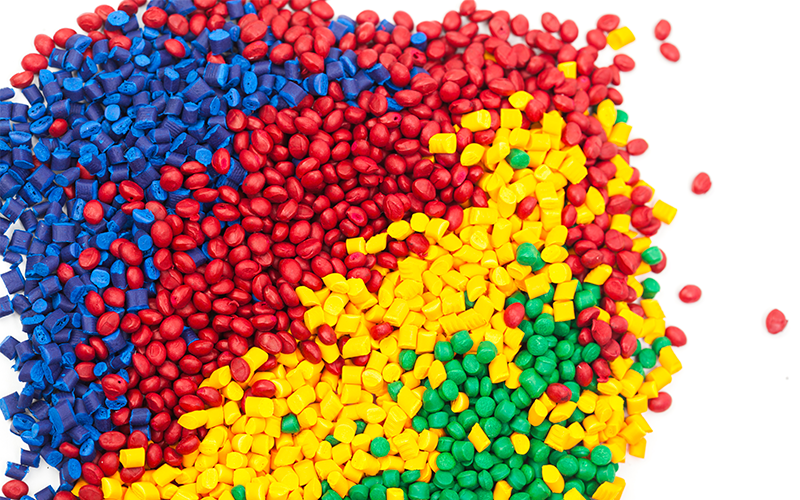

Colibri color matching software’s powerful calculation and control capabilities in dealing with complex colors and special materials with excellent performance, can accurately calculate the ratio of pigments, dyes in different materials, in the actual application of Xinliang Plastics show a variety of advantages.

Xinliang Plastic once received a multi-material matching makeup packaging order, the color requirement is very high and involves different substrates. In the traditional way, the adjustment was difficult and the period was long. However, through the Colibri system, Xinliang Plastics was able to quickly obtain accurate formulas for different materials, and the first sampling was close to the standard color, and two fine-tuning times were confirmed by the customer, which shortened the whole development cycle by nearly one-third.