In the world of paint and coatings, color is more than aesthetic. It plays a critical role in everything from safety and thermal efficiency to branding and durability. With applications ranging from architectural and automotive to aerospace and marine, manufacturers face increasing demands for fast, accurate, and sustainable color performance.

Add to that the volatility in raw material availability, and it becomes clear that having a robust system for color management in paint and coatings isn’t just a nice-to-have—it’s essential for competitive success.

Diverse Applications, Unified Color Strategy

Paint and coating products vary widely, but color consistency remains a shared priority:

Architectural Coatings: Account for more than half of global paint volume. Consistent color is vital for interior and exterior harmony in residential and commercial buildings.

Coil Coatings: Used in automotive and appliance manufacturing, these demand high durability and often require heat-reflective properties.

Powder Coatings: A sustainable solution that reduces VOC emissions and overspray waste.

Marine & Aerospace Coatings: Engineered for extreme environments, where color influences performance and regulatory compliance.

Each segment benefits from digital workflows that reduce the risk of human error, shorten development cycles, and ensure consistency across surfaces and gloss levels.

Why Digital Color Management Is Essential

Color perception varies by individual and is influenced by surface texture, lighting, and finish. That’s why relying on visual assessments alone can lead to mismatched batches and costly rework. Implementing digital color management eliminates these variables and offers several advantages:

Color Accuracy

Spectrophotometers ensure precise, objective measurement across gloss, matte, or textured finishes. Datacolor instruments are known for high inter-instrument agreement, making them ideal for multi-site operations.

Faster Approvals

Digital workflows eliminate the need to ship physical samples. Fan decks can be replaced with searchable digital color libraries, enabling faster palette development and sample approval.

Data-Driven Decisions

By comparing new measurements with archived data, teams can optimize formulations for cost, sustainability, or performance—based on real-world data.

Global Collaboration

Cloud-based platforms ensure that everyone in the supply chain is working from the same data, no matter their location.

Efficiency, Sustainability, and Scale

Sustainability is a growing priority in the coatings industry. Every formulation misstep means wasted materials, energy, and time. Color is often one of the most waste-prone steps, especially without the right technology in place.

A digital color management system allows manufacturers to: – Reduce scrap and rework by achieving first-shot color matches – Select the most sustainable and cost-effective raw materials – Reuse or re-formulate off-color batches

With smart formulation software, companies can design recipes that balance performance with environmental responsibility.

Real-World Success with Datacolor

Pison Stream Solutions needed accurate, consistent color control across multiple locations. With Datacolor spectrophotometers and QC software, they achieved seamless data sharing and minimized the need for redundant measurement.

Crown Paints, an established UK brand, modernized its legacy systems with Datacolor technology. The result: faster development of new colors, reduced use of base paints, and improved opacity across formulations.

Achieve More with Datacolor

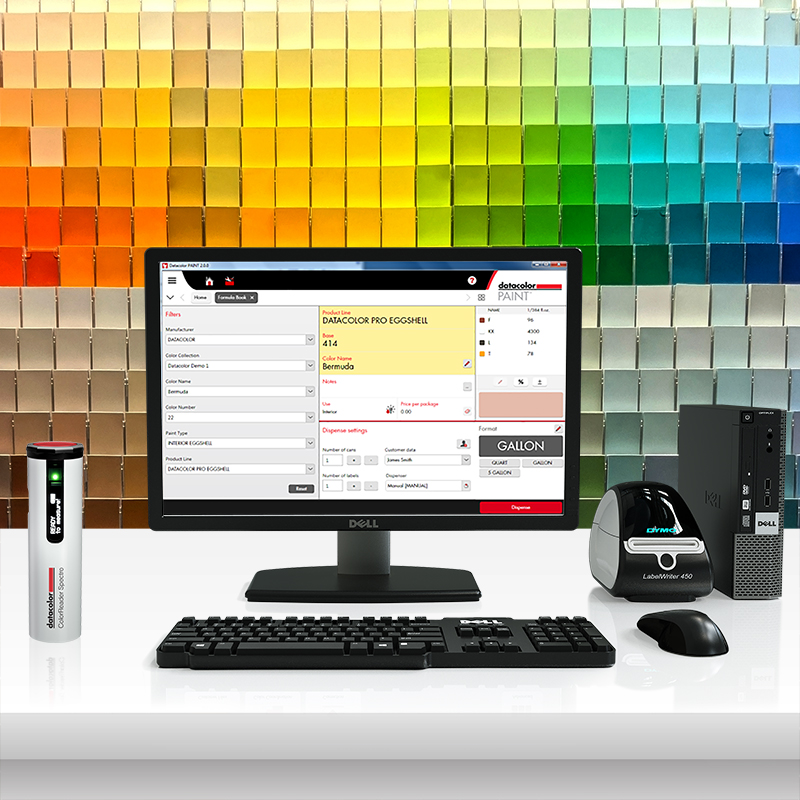

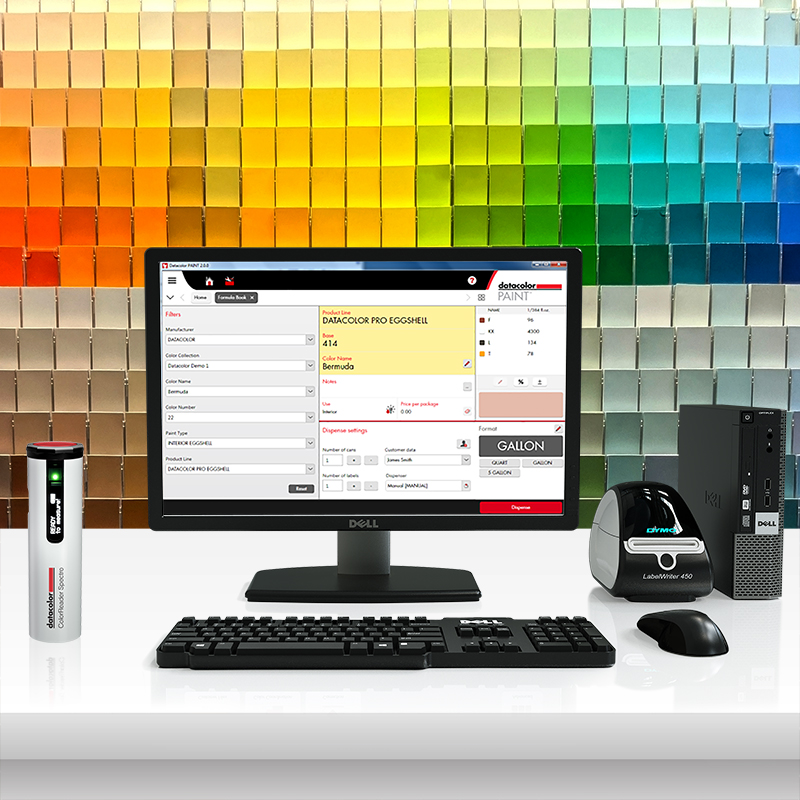

From inspiration to final production, Datacolor provides tools to help paint and coatings manufacturers succeed:

Formulation Software: Optimize recipes with precision, speed, and flexibility

Spectrophotometers: Measure consistently across complex surfaces and finishes

QC Software: Track batch consistency and maintain color standards

Cloud Integration: Collaborate globally with a single source of truth for color

Whether you’re streamlining new product development or adapting to volatile supply chains, digital color control gives you the confidence and agility to succeed in today’s fast-paced market.

Explore how Datacolor can support your next color success story.