In textile production, color decisions can make or break a collection. From initial design to final delivery, even a minor mismatch can cause delays, increased costs, and excess waste. With tight deadlines, global supply chains, and rising sustainability expectations, getting color right the first time is no longer optional—it’s a strategic necessity.

A digital approach to color management in textiles offers measurable advantages in efficiency, consistency, and sustainability.

The Challenge of Color in Fashion and Fabric

The textile color workflow is complex. Designers draw inspiration from seasonal trends, then collaborate with product teams to finalize palettes. Materials are evaluated for compatibility. Color standards are established, but translating those ideas into dyed fabric can introduce subjective interpretation.

Physical samples are often shipped multiple times across the globe. Delays in approvals and inconsistent lab dips can slow the production cycle and increase waste. Up to 75% of proposed colors may never make it to production—but still consume valuable resources.

Why Digital Color Management Changes Everything

Implementing a digital workflow transforms how color is specified, measured, and approved throughout the textile value chain.

Streamlined Design

Designers can select and communicate colors from global standard libraries. Palette creation becomes faster and more accurate.

Faster Dye Development

Datacolor formulation tools improve recipe accuracy and provide reliable first-shot matches, reducing the need for costly re-dyes.

Objective Evaluation

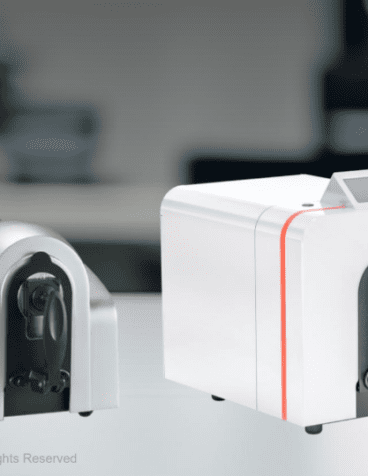

Spectrophotometers remove subjectivity from color assessments. Even challenging materials like buttons, lace, or textured fabrics can be measured accurately.

Automation in the Lab

Lab equipment automates dye dispensing and minimizes errors. Dyers can trust the consistency of each batch.

Supply Chain Alignment

Digital communication ensures every stakeholder is working from the same data—no matter the location or language.

Supporting Speed and Sustainability

The fashion industry is under growing pressure to reduce environmental impact. Textile dyeing is responsible for 20% of global wastewater. Color management can be a major contributor to waste reduction.

Digital systems help manufacturers: – Avoid over-dyeing by achieving accurate first matches – Optimize recipes to use fewer or more sustainable colorants – Re-use or reassign off-color batches

These practices support circularity and help organizations meet sustainability goals while maintaining delivery speed.

Success Stories from the Textile Industry

Amann Group, a global thread manufacturer, reduced rework and improved decision-making with Datacolor systems. By standardizing their workflow and using advanced spectrophotometers, they achieved better reproducibility and operational efficiency.

DK Company found inconsistent standards across global locations caused delays and high shipping costs. After switching to a digital workflow with Datacolor, they accelerated time to market by up to 15 days and reduced shipping by eliminating physical lab dip approvals.

A Complete Solution for Color Management

Datacolor offers an end-to-end suite of tools for textile color control:

– Color Formulation Software: Achieve accurate, optimized dye recipes

– Spectrophotometers: Objectively measure color across fabric types and finishes

– Lab Dispensing Systems: Automate recipe development for speed and precision

– QC and Communication Tools: Align partners through digital color data

With Datacolor, you can eliminate guesswork, improve product quality, and reduce both time and environmental impact.