For manufacturers and consumers alike, color is a key indicator of quality. In the plastics industry, however, achieving consistent, accurate color is particularly complex. Plastic materials can be glossy or matte, opaque or transparent, smooth or textured. These characteristics—combined with the need to coordinate with other materials like metal or fabric—make precise color control essential.

Each error in color matching can lead to wasted material, lost time, and higher production costs. For manufacturers looking to boost efficiency and meet sustainability goals, the solution lies in establishing a reliable, end-to-end system for color management in plastics.

From Masterbatch to Final Product: Where Color Decisions Happen

The color journey of a plastic product begins with the masterbatcher or compounder. These suppliers blend resins with pigments and additives to create color-infused pellets tailored to the customer’s performance needs—such as UV resistance, heat stability, or moisture protection. Some colorants, like titanium white or carbon black, also serve functional purposes beyond aesthetics.

Converters then take these pellets and use shaping processes—such as injection molding or extrusion—to form the final product. At this stage, additional additives may be included, and quality control becomes critical. Products are evaluated for color fidelity, uniformity, and defects before shipment.

Digital Color Management: A Strategic Advantage

Faster Time to Market

Streamlined digital communication ensures faster color approvals and reduces delays from shipping physical samples. This is vital when production needs to pivot due to ingredient shortages or specification changes.

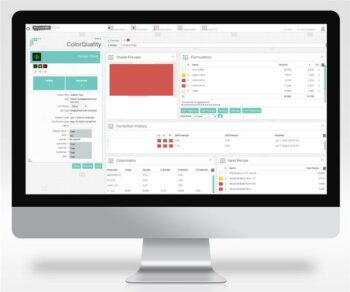

First-Shot Color Accuracy

Using formulation software like Datacolor Colibri, manufacturers can develop precise recipes based on physical characteristics and available ingredients. This reduces costly trial-and-error cycles and supports quicker scale-up from lab to production.

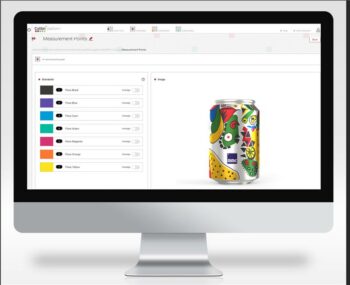

Seamless Global Collaboration

Cloud-based platforms like Colibri Hub enable teams across regions to access and evaluate the same color data. This minimizes versioning issues, improves responsiveness, and supports agile decision-making across the supply chain.

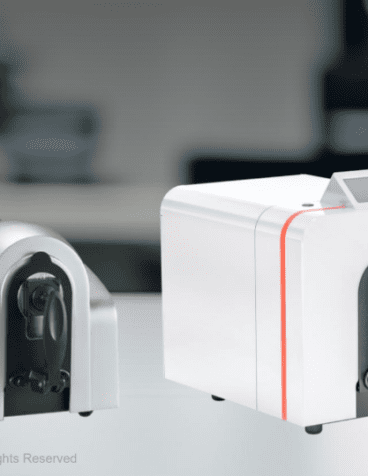

Reliable Measurement for Complex Surfaces

Plastics present unique measurement challenges. Datacolor spectrophotometers are designed to account for gloss, opacity, and texture—ensuring consistent results. Built-in temperature sensors prevent inaccurate readings caused by thermochromic effects, ensuring samples are measured only when cooled to spec.

Sustainability Starts with First-Shot Success

In the pursuit of sustainability, minimizing waste is essential. Incorrectly colored masterbatches often can’t be salvaged, resulting in wasted raw materials and energy. Achieving accurate, first-shot colors significantly reduces rework, conserves resources, and supports environmental objectives.

Digital color management enables recipe optimization before full-scale production, allowing manufacturers to balance quality, efficiency, and sustainability with precision.

Proven Results from Industry Leaders

Two global manufacturers have experienced the value of partnering with Datacolor:

Pioneer, a Thai-based plastics company, replaced subjective visual matching with Datacolor’s digital tools. This enabled fast, objective color evaluations across their supply chain—cutting waste and improving efficiency.

Sekisui Polymer Innovations enhanced their QC processes using high-performance Datacolor spectrophotometers and standardized sample conditioning. The result: improved repeatability and shorter lead times for color approvals.

Strengthen Your Workflow with Integrated Solutions

Datacolor supports every stage of the plastics color lifecycle: – Formulation with Colibri for optimized, compliant recipes

– Measurement & QC with spectrophotometers adapted for plastic-specific challenges

– Data communication through global cloud access

– System integrations that link with ERP or PLM tools to suggest formulas based on available stock or budget limits

Ready to Take Control of Your Color?

For plastics manufacturers, the cost of getting color wrong is high—but the reward for getting it right the first time is even greater. Digital color management reduces waste, improves accuracy, and delivers the consistency customers expect.

Datacolor offers tailored solutions that integrate across your workflow—from lab to production—helping your team make data-driven decisions that save time and resources.

Explore how Datacolor can support your color management strategy and keep you competitive in a fast-moving, high-stakes industry.